Machinery Maintenance Practical

OBJECTIVES:

At the end of the study of VI Semester the student will be able to :

1. Know about handling and application of tools like Pipe wrench, Spanner, Vernier Caliper, Micrometer, Feeler Gauge, Dial Gauge and Screw Driver.

2. Learn removing, tensioning and mounting of various drives (Belt and Chain).

3. Check the levelling/alignment of the machine or motor surface.

4. Check the performance of Gripper.

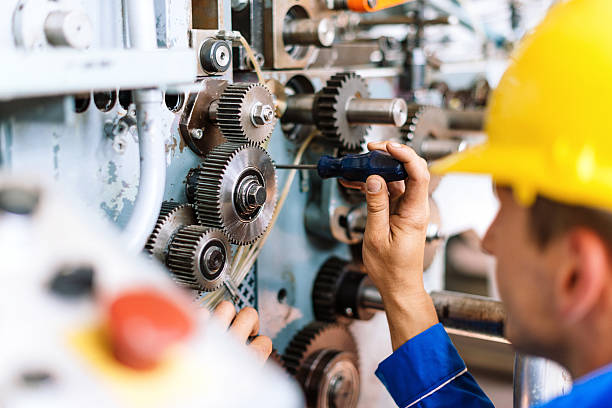

5. Learn assembling and dismantling of bearings/gears/cams/springs.

6. Perform Oil changing, air filter cleaning and lubricating the points.

7. Check and replace electrical component.

8. Perform the solid print test for identifying mechanical problems in the machine.

9. Learn about removing of damaged screws/pins/bolts and nuts.

10. Check the sensors & detectors.

- Teacher: Subash SIGA

This course deals with principles of management, estimating and

costing, planning for print production, accounting and budgeting and human

resource management etc.

- Manager: Wasim Raja

This course deals with maintenance management, power transmission, mechanical and electrical elements, lubrication and reconditioning and maintenance of mechanisms etc.

- Manager: Wasim Raja